Farriers Tools

Hot Shoeing Process:

-

The farrier picks up the foot & places between their knees (front foot) or rests on their thighs (hind foot)

-

All the clenches are raised using the buffer and the hammer

-

The shoe is removed using the pinchers. Levering both heels a quarter way down the shoe inwards.

-

The length of the hoof wall is assessed in relation to the sole, trimmed as

required with the hoof cutters. Checking for hoof balance - A rasp is then used to level all surfaces

- The shoe is measured/ tried on ... correct size chosen and placed into the forge.

- The shoe is then shapped to match the horse's hoof by hammering it against the anvil. Being held with the use of the pritchel so the the farrier does not burn themselves.

- The shoe is repeatedly checked against the hoof during the shaping process. (A hot shoe pressed against the trimmed hoof wall clearly leaves marks especially on any uneven areas)

- Correct shape achieved, the shoe is then cooled in water before being nailed on.

- Once the finally fit has been checked, the shoe is nailed on carefully to avoid the sensitive laminae

- The ends of the nails are exposed on the outer hoof wall, these are then twisted off with the hammer, and bent over with the hoof clenchers. - the horses hoof is often rested on a tripod during this process enabling the farrier to use 2 hands.

- sharp edges of the clenches are then filed off with the rasp. The hoof wall is rasped where it meets the shoe. (This reduces risks of cracks in the hoof) Clips are gentle tapped into place.

Farriers Tools and their Uses:

Buffer

Used to raise clenches

Driving Hammer

Used together with the buffer to help raise the clenches.

Hammers nails into hoof.

Trims/ twists off the ends of the nails.

Pinchers

Used to lever off the shoe

Drawing Knife

Used to trim the horse, sole and frog.

Rasp

Used to level the surface of the hoof wall and to finish off the edge once the shoe I on.

Like a huge nail file.

Nail Clencher

Folds the end of the nail over to create the clench. To make the clench flush with the hoof wall.

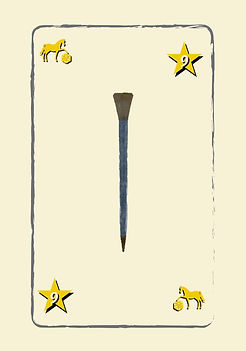

Nail

Used to hold the shoe in place.

Driven at an outwards angle, so that the nail tips go through to the top of the hoof wall, special attention being paid to avoid the sensitive laminae.

(some modern shoes use glue instead of nails to hold the shoe in place)

Tripod

Used to help support the horses hoof, to enable the farrier to use both hands, particularly used during the clenching up phase.

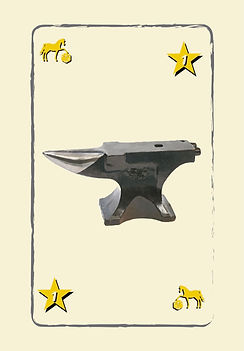

Anvil

Used as the work surface during the shaping phase of the hot shoe.

The farrier is able to hammer, bend and shape the shoe to fit the horses hoof.

(The hoof shouldn't be made to fit the shoe)

Hoof Cutters

Used to set trim away the excess hoof wall growth, enabling the farrier to maintain correct hoof balance for the horse.

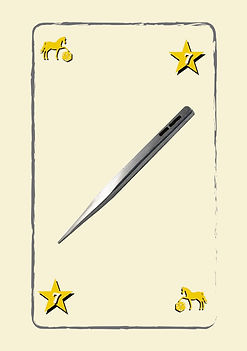

Pritchel

Used to punch hole into shoes.

They can be used to widen nail holes when required

Also used to help hold and stabilise the hot shoe during the shaping phase and to carry the shoe from anvil to the horse's hoof to 'try on' the shoe before it is cooled.

Fire Tongs

Used to hold hot horse shoes, Used to take the shoe In and out of the forge and during the shaping phase of the shoe. some farriers will use these to transport the shoe from anvil to horses hoof whereas some prefer to use the pitchel for this.